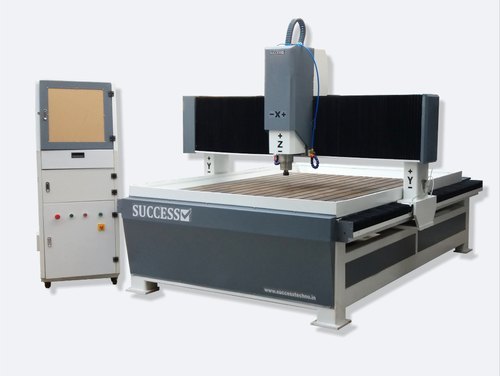

CNC Pattern Making Machine

CNC Pattern Making Machine Specification

- Product Type

- CNC Pattern Making Machine

- General Use

- Pattern and Mould Making

- Material

- Wood, Plastic, Foam, Aluminum

- Type

- CNC Router Machine

- Capacity

- Continuous Operation

- Weight (kg)

- 2200 kg (approx.)

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Yes

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 5-10 kW (approx.)

- Rigidity

- High

- Voltage

- 220V/380V/415V

- Motor

- AC Servo Motor

- Table Size

- Customizable / 1500 x 3000 mm (as example)

- Spindle Speed

- 0-24000 RPM

- Axial Choice

- 3/4-Axis

- Dimension (L*W*H)

- 2500 x 2200 x 1800 mm (approx.)

- Feature

- High Precision, Fast Processing, User-friendly Interface

- Color

- Blue/White

- Controller

- Industrial CNC Controller

- Safety System

- Emergency Stop, Safety Enclosure

- Drive System

- Servo/Stepper Motor Drive

- Working Accuracy

- ±0.05 mm

- Cooling System

- Water Cooling/ Air Cooling

- Software Compatibility

- G-Code, NC, DXF

- Noise Level

- Low

- Traveling Speed

- Up to 25 m/min

- Tool Holder Type

- ER32/ER40

- Spindle Power

- 6 kW / 9 kW (as per configuration)

- Application

- Automotive, Aerospace, Foundry, Prototyping

- Lubrication System

- Automatic Lubrication

- Dust Collection

- Yes, Optional

CNC Pattern Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- Unit

- Delivery Time

- 4 Week

- Packaging Details

- As Per Product

- Main Export Market(s)

- Africa, Middle East, Asia

- Main Domestic Market

- All India

About CNC Pattern Making Machine

Along with our superior market experience and knowledge, we manufacture and export a wide range of CNC Pattern Making Machine. Known for excellent functionality and longer service life, our entire range is used for making uniform patterns on metallic surfaces or sheets. These machines are assembled by utilizing excellent quality components with the help of advance tools and techniques at well equipped production unit. This CNC Pattern Making Machine after proper testing on several industrial standards, can be easily availed at best market price.

Features:

- Easy to operate

- Durable structure

- Light weight machine

Technical Specifications :

| Working (X, Y, Z) | 1500 X 3000 x 500 mm |

| Spindle Motor | 6 KW (Air Cooled) or as per applications |

| Maximum Running Speed (without load) | 25 m/min |

| Rotating Speed of Tool | 0-18000 RPM |

| Engraving Tools | 3, 4, 6, 12.7 mm |

| Dictate Format | HPGL , G-Code |

| Repeated Location | 0.025 mm |

| Driving System | Servo Motor (OPtional : Stepper Motor) |

| Operating System | PCI Based Controller |

| Power Supply | AC 420V/3PH |

High Precision and Fast Processing

Achieve superior pattern-making accuracy and speed, thanks to advanced spindle options and precision drive systems. The CNC Pattern Making Machine offers exceptional 0.05 mm tolerance and traverses up to 25 m/min, significantly boosting both quality and throughput in pattern and mould creation.

Versatile Material & Application Support

This machine can cut and process a range of materials including wood, plastic, foam, and aluminum, making it versatile for industries like automotive, aerospace, and foundries. Customizable table size and axial options allow seamless adaptation to specific production needs.

User Safety and Efficient Operation

Equipped with vital safety featuressuch as emergency stop, safety enclosures, and optional dust collectionthe machine prioritizes operator wellbeing. Automatic lubrication and intelligent controller integration contribute to user-friendliness and reliable, low-maintenance operation.

FAQs of CNC Pattern Making Machine:

Q: How does the CNC Pattern Making Machine ensure high precision during operation?

A: The machine utilizes a servo or stepper motor drive system, an industrial CNC controller, and high rigidity construction to achieve a working accuracy of 0.05 mm. Automatic lubrication and stable AC servo motors further contribute to precise, repeatable performance.Q: What materials can be processed using this CNC Pattern Making Machine?

A: This machine is capable of processing a wide variety of materials such as wood, plastic, foam, and aluminum, making it suitable for applications in automotive, aerospace, foundry, and prototyping industries.Q: When is it advisable to use water cooling or air cooling with this machine?

A: The cooling system, offering water or air cooling, should be chosen based on the material being processed and the operational load. Water cooling is ideal for intensive, high-heat operations, while air cooling is sufficient for lighter, less heat-generating tasks.Q: Where can this CNC Router be installed for optimal use?

A: Designed for industrial environments, the machine is best installed in workshops or production facilities with adequate space and power supply (220V/380V/415V), and where safety enclosures and dust collection can be effectively implemented.Q: What is the operational process for creating patterns using this CNC machine?

A: Operators import compatible design files (G-Code, NC, DXF) via the controller, set up the material on the customizable table size, select appropriate tool holders (ER32/ER40), and manage spindle speeds up to 24,000 RPM for efficient, accurate pattern cutting.Q: What benefits does the automatic lubrication and safety system provide?

A: The automatic lubrication system ensures seamless operation with minimal downtime and reduced wear, while the integrated emergency stop and safety enclosure safeguard users, contributing to a more productive and secure working environment.Q: How does the machine enhance usability for operators?

A: Featuring a user-friendly interface, industrial PLC control, and compatibility with widely used pattern-making software, the machine simplifies setup and operation, allowing even less-experienced users to achieve professional results with minimal training.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Engraving Machine Category

Industrial CNC Engraving Machine

Minimum Order Quantity : 01 Unit

Weight (kg) : 950 kg

Power Source : Electric

Product Type : Industrial CNC Engraving Machine

Color : Other, White/Blue

CNC Wood Engraving Router Machine

Weight (kg) : 1200 Kg

Power Source : Electric

Product Type : CNC Wood Engraving Router Machine

Color : Other, White & Blue

CNC Engraving & Router Machine with Rotary Attachment

Weight (kg) : Approx. 1200 1600 kg

Power Source : Electric

Product Type : CNC Engraving & Router Machine with Rotary Attachment

Color : Other, Blue & White

Cnc Engraving Router Machine

Weight (kg) : Approx. 1000 kg

Power Source : Electric

Product Type : CNC Engraving Router Machine

Color : Other, Blue & White

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS