Laser Ply

Laser Ply Specification

- Accuracy Level

- 0.03 mm

- Marking Speed

- 500 7000 mm/s

- Z axis transmission

- Manual adjustment

- Laser Life

- Up to 10,000 hours

- Machine Type

- Laser Engraving & Cutting Machine

- Y axis Transmission

- High precision guide rail

- Laser Wave Length

- 10.64 m

- Marking Area

- 600 x 400 mm

- Laser Type

- CO2 Sealed Laser Tube

- Power Supply

- AC 220V / 50Hz

- Marking Depth

- 2 mm (Depends on material)

- Voltage

- 220V

- Weight

- 60 kg

- Control System

- DSP Control

- X axis Transmission

- High precision guide rail

- Laser Source

- Glass CO2

- Working Temperature

- 0C 45C

- Design

- Floor standing cabinet

- Condition

- New

- Engraving Area

- 600 x 400 mm

- Engraving Speed

- 500 7000 mm/s

- CNC

- Yes

- Cooling Mode

- Water Cooling

- Applicable Material

- Wood, Acrylic, MDF, Leather, Paper, Rubber, Fabric, Glass

- Dimensions

- 1100 x 800 x 600 mm

- Drive Type

- Belt Drive

- Motor

- Stepper Motor

- Working Area

- 600 x 400 mm

- Focus Mode

- Manual/Auto Focus

- Software Compatibility

- CorelDRAW, AutoCAD

- Lighting Mode

- Red Light Positioning

- Operator Panel

- Digital LCD Display

- Gross Power

- 1000W

- Operation Mode

- Continuous/Intermittent

- Supported File Format

- PLT, DXF, BMP, AI, JPG

- Environment Requirement

- Dust Free, Stable Temperature

- Max Cutting Thickness

- 10 mm (Acrylic)

- Interface

- USB port

- Safety Features

- Emergency Stop, Protective Cover

About Laser Ply

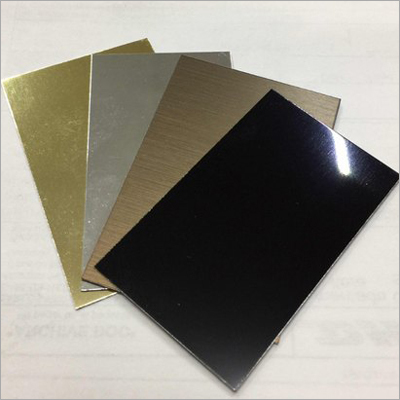

Laser Ply sheet offered by our company is made up by using top-grade medium to high density plywood that gives high strength to weight ratio with excellent thermal and impact resistance. It is commonly used within laser cutting machines to provide protection against high intensity laser beams. It comes in various customized sizes as per the order placed by our customers. The offered plywood sheet can be delivered to our clients with an assurance of fast and safe delivery at a reasonable price.

Precise and Efficient Cutting Power

Engineered for professionals, this laser engraving and cutting machine delivers up to 10 mm acrylic cutting depth and 0.03 mm accuracy. Its robust design and stepper motor-driven axes ensure smooth, reliable motion, while the DSP control system guarantees precision every time, making it a reliable solution for intricate and high-volume tasks alike.

User-Friendly Operation and Broad Compatibility

With both manual and automatic focusing, a digital LCD display operator panel, and red light positioning, setup and operations are intuitive. The machine interfaces via USB and works seamlessly with CorelDRAW and AutoCAD, supporting popular file formats (PLT, DXF, BMP, AI, JPG) to accommodate a wide range of design workflows.

Enhanced Safety and Durability

Equipped with essential safety featureslike an emergency stop button and protective coverLaser Ply keeps operators safe throughout the process. Its water cooling system extends the CO2 laser tubes life (up to 10,000 hours), and a dust-free, stable-temperature workspace ensures optimal machine longevity and performance.

FAQs of Laser Ply:

Q: How do I operate the Laser Ply for both engraving and cutting tasks?

A: Laser Ply offers flexible operation via a digital LCD panel, allowing you to select engraving or cutting modes. After setting your file (such as PLT, DXF, BMP, AI, or JPG) through compatible software, use the manual or auto focus options and red light positioning for precise alignment. The process is simple for users familiar with CorelDRAW or AutoCAD.Q: What materials and thicknesses can the machine handle?

A: This machine is designed for a variety of materials, including wood, acrylic (up to 10 mm thickness), MDF, leather, paper, rubber, fabric, and glass. Marking depths are material-dependent, but generally 2 mm. Its robust, high-precision mechanism ensures clean and consistent results across surfaces.Q: When is routine maintenance required for optimal performance?

A: Its recommended to periodically check the water cooling system, ensure the workspace remains dust-free, and inspect optical and transmission parts for cleanliness and wear. Regular maintenance extends the laser tubes lifespan and sustains high-quality output.Q: Where should the Laser Ply be installed for the best results?

A: Install the machine in an environment that is dust-free and maintains a stable temperature between 0C and 45C. Proper ventilation and proximity to an AC 220V / 50Hz power supply are essential for safe and uninterrupted operation, ensuring optimal performance and safety.Q: What are the key safety features of this machine?

A: For user safety, Laser Ply includes an emergency stop button and a protective cover. The system is also designed to operate only when environmental requirements are met, and its digital controls help prevent accidental operation errors.Q: How does using Laser Ply benefit my workflow or business?

A: Laser Ply offers high-speed, precise engraving and cutting, significantly increasing productivity and reducing error. Its compatibility with major design software and support for multiple file formats allow for seamless integration into existing business processes. The durable construction and reliable safety features help ensure long-term, cost-effective operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Consumables Category

Laser Foil For Laser Engravers

Applicable Material : Plastic Metal, Other

Condition : New

Design : Other, Laser engraving foil

Power Supply : None

Voltage : None

Drive Type : Manual

Led Lamp Base

Applicable Material : Plastic

Condition : New

Design : Other, Round Black Base

Power Supply : USB powered

Voltage : 5V

Drive Type : Electronic

Manual Acrylic Letter Bending Tool

Applicable Material : Acrylic

Condition : New

Design : Ergonomic, Other

Power Supply : Electric

Voltage : Standard

Drive Type : Manual

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS