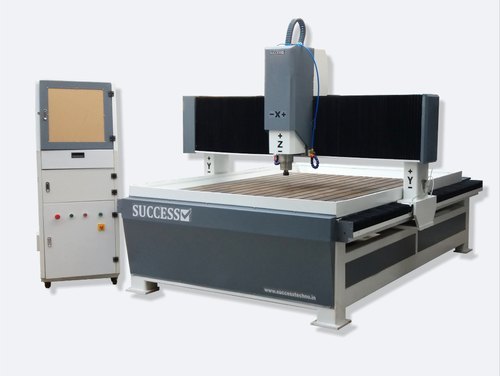

CNC Router Engraving Machine

CNC Router Engraving Machine Specification

- Product Type

- CNC Router Engraving Machine

- General Use

- Wood, MDF, Acrylic, PVC, Soft Metals Engraving and Cutting

- Material

- Steel and Aluminum Structure

- Type

- CNC Router

- Capacity

- Heavy Duty Industrial Use

- Weight (kg)

- Approx. 1200 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Yes

- Bar Feeder

- Not Included

- Power Source

- Electric

- Power Consumption

- 3 kW

- Rigidity

- High

- Voltage

- 220V/380V

- Motor

- Stepper Motor

- Table Size

- 1300 mm x 2500 mm

- Spindle Speed

- 24000 RPM

- Axial Choice

- 3, 4, or 5 Axis (Configurable)

- Dimension (L*W*H)

- approximately 2000 mm x 3000 mm x 1600 mm

- Feature

- Automatic Tool Changer, Precision Linear Guide, Water Cooling

- Color

- Blue and White

- Traveling Speed

- Up to 30000 mm/min

- Display Interface

- LCD

- Drive Type

- Stepper/Servo Motor

- Operating System

- Windows Compatible

- Lubrication System

- Automatic

- Max Material Thickness

- 150 mm

- Software Compatibility

- ARTCAM, Type3, Ucancam, JD Paint, CorelDraw

- Dust Collector

- Optional

- Cooling Method

- Water Cooling System for Spindle

- Clamping System

- Vacuum/Clamp Table Options

- Repeatability

- ±0.02 mm

- Working Accuracy

- ±0.05 mm

- Control System

- DSP Control/NC Studio/Mach3

- Spindle Power

- 3.2 kW Air/Water Cooled

- Transmission

- Ball Screw for Z Axis, Rack & Pinion for X & Y Axis

About CNC Router Engraving Machine

Backed by the immense industry knowledge and experience, we are manufacturing and exporting a quality assortment of CNC Router Engraving Machine. Our entire range is demanded in mechanical and heavy engineering industry for engraving rough work piece and monitored through CNC panels. This machine is assembled in line with set industry standards by using finest grade components with the help of contemporary tools and techniques. We offer this CNC Router Engraving Machine to our clients in several power capacities at market leading rates.

Features:

- Easy to install

- Rust proof coating

- Superior finish

Technical Specifications :

| MODEL | ST1325 / ST1325V |

| Working (X, Y, Z) | 1300 X 2500 x 200 mm |

| Spindle Motor | HSD 6KW air-cooled spindle motor from Italy |

| Motion Speed | 25000 mm/min |

| Rotating Speed of spindle | 0-18000 rpm |

| Engraving Tool | 3.175, 4, 6, 12.7 mm |

| Dictate Format | HPGL, G-code |

| Resolution | 0.025mm |

Unmatched Precision and Speed

Featuring a combination of ball screw and rack & pinion transmission, this CNC router achieves exceptional repeatability of 0.02 mm and working accuracy of 0.05 mm. The industrial-grade spindle operates at 24,000 RPM, ensuring high-quality engraving and cutting across complex materials and designs. High rigidity and robust structure prevent vibrations, delivering reliable results even at speeds up to 30,000 mm/min.

Flexible and User-Oriented Operation

The machine comes with customizable axis options (3, 4, or 5 axis) and supports both vacuum and clamp tables, adapting easily to various project needs. Its intuitive DSP, NC Studio, or Mach3 control systems and LCD interface make operation straightforward, even for intricate tasks. The automatic lubrication and optional dust collection keep maintenance hassle-free and your workspace clean.

Industry-Ready for Heavy-Duty Use

Engineered for demanding environments, it supports material thickness up to 150 mm and features a strong steel-aluminum frame that supports approx. 1,200 kg. The system is compatible with popular design software, streamlining your workflow from concept to finished product. Trusted by exporters and manufacturers across India, its ideal for industrial engraving and cutting applications.

FAQs of CNC Router Engraving Machine:

Q: How does the CNC router ensure precise and repeatable engraving results?

A: The machine utilizes a high-rigidity frame, precision ball screw transmission for the Z axis, and rack & pinion transmission for the X and Y axes. Combined with advanced control systems and stepper or servo motors, it achieves a working accuracy of 0.05 mm and repeatability of 0.02 mm, ensuring consistently accurate outputs.Q: What materials can be processed with this CNC router engraving machine?

A: This versatile CNC router is designed to engrave and cut a wide range of materials, including wood, MDF, acrylic, PVC, and soft metals, making it suitable for furniture, signage, and industrial component applications.Q: When should I use the automatic tool changer feature?

A: The automatic tool changer is beneficial when your projects require multiple tools for varied cuts or engraving operations. It reduces production downtime by quickly swapping tools, improving workflow efficiency and overall productivity in high-volume or multi-process tasks.Q: Where is this CNC router manufactured and supported?

A: This CNC router engraving machine is manufactured, exported, and supported in India, catering to both domestic and international clients, with after-sales service and support provided by the manufacturer and suppliers.Q: What is the process of operating this CNC router from design to execution?

A: Begin by creating or importing your design using compatible software such as ARTCAM, Type3, Ucancam, JD Paint, or CorelDraw. Once the design is ready, transfer it to the CNC controller (DSP/NC Studio/Mach3) and configure the required settings. Mount your material using the vacuum or clamp table, select the necessary tools, and begin the automated engraving or cutting process. The LCD interface and systematic workflow simplify operation even for intricate projects.Q: How does the machines cooling method benefit long-term performance?

A: The spindle is equipped with an efficient water cooling system that maintains optimal temperature even during prolonged use. This prevents overheating, reduces tool wear, and extends both spindle and tool life, ensuring reliable, high-performance operation in industrial environments.Q: What are the user advantages of the automatic lubrication and optional dust collector features?

A: The automatic lubrication system ensures that moving parts remain well-maintained for smooth, low-wear operation without manual intervention. The optional dust collector keeps the work area clean, reducing clean-up time and maintaining air quality, which is particularly valuable during prolonged or intensive use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Engraving Machine Category

CNC Engraving Machine

Price 890000 INR / Unit

Minimum Order Quantity : 01 Unit

Power Source : Electric

Weight (kg) : 680 kg

Product Type : CNC Engraving Machine

Color : Other, Grey

Industrial CNC Engraving Machine

Minimum Order Quantity : 01 Unit

Power Source : Electric

Weight (kg) : 950 kg

Product Type : Industrial CNC Engraving Machine

Color : Other, White/Blue

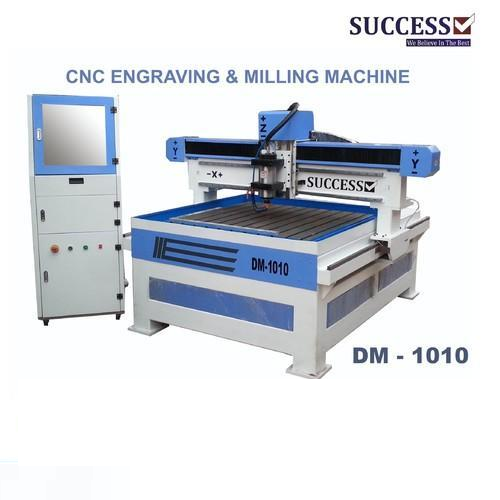

CNC Engraving & Milling Machine

Power Source : Electric

Weight (kg) : 1800 kg

Product Type : CNC Engraving & Milling Machine

Color : Other, Grey & Blue

CNC Engraving Router Machine 2 spindle

Power Source : Electric

Weight (kg) : Approximately 1200 kg

Product Type : CNC Engraving Router Machine

Color : Other, Blue and White

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS