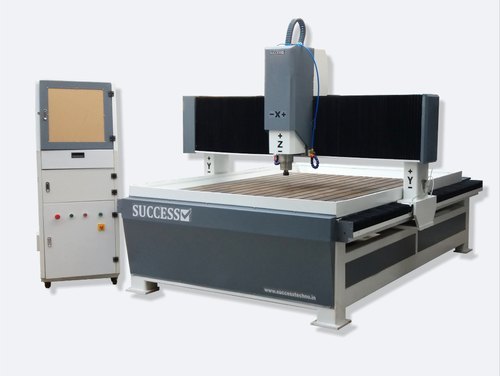

CNC Engraving Router Machine 2 spindle

CNC Engraving Router Machine 2 spindle Specification

- Product Type

- CNC Engraving Router Machine

- General Use

- Wood, MDF, Acrylic, PVC, Aluminium engraving/cutting

- Material

- Steel Body, Aluminium Table

- Type

- Multi Spindle CNC Router

- Capacity

- Medium to large sheet processing

- Weight (kg)

- Approximately 1200 kg

- Computerized

- Yes

- Automatic

- Fully automatic operation

- PLC Control

- Yes

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 3-4 kW (approx, depending on spindle type)

- Rigidity

- High structural rigidity for precision

- Voltage

- 220V/380V (customizable)

- Motor

- Stepper/Servo Motor

- Table Size

- 1300 mm x 2500 mm

- Spindle Speed

- 0-24000 rpm (variable)

- Axial Choice

- XYZ

- Dimension (L*W*H)

- 2100 mm x 3000 mm x 1700 mm

- Feature

- Double spindle for simultaneous operation

- Color

- Blue and White

- Spindle Power

- 3.5 kW x 2 (two spindles)

- Working Voltage

- AC 220V/50Hz or 380V/50Hz (based on configuration)

- Dust Collector

- Optional external system

- Application Industries

- Signage, furniture, panel making, advertising, decoration

- Software Compatibility

- Compatible with ArtCAM, Type3, Aspire, etc.

- Work Environment

- 0-45C, 85% RH

- Repositioning Accuracy

- 0.02 mm

- Supported File Formats

- G-code, HPGL, DXF, etc.

- Max Travelling Speed

- >25,000 mm/min

- Safety Protection

- Emergency stop, limit switches

- Cooling Type

- Water-cooled spindle

- Transmission Method

- Belt transmission (X/Y), Ball screw (Z)

- Drive System

- Rack and pinion for X/Y axis, Ball screw for Z axis

- Control System

- DSP handheld controller/NC Studio (optional)

About CNC Engraving Router Machine 2 spindle

CNC Engraving Router Machine 2 spindle is a specialized machining unit that is used for engraving and cutting of materials such as wood, plastic, aluminum, and composite materials. It is equipped with a simple to use computer numerical control systems to precisely control the movement spindles that allow you to perform multiple cutting and engraving operations with high precision and accuracy. CNC Engraving Router Machine 2 spindle can be used in small to large scale industries due to its increase productivity and efficiency. Get this fully automated machine with an assurance of fast and safe delivery

Double Spindle Efficiency

The routers dual spindles allow for simultaneous engraving or cutting of identical or different patterns, speeding up productivity. This feature is especially beneficial for batch processing in signage, furniture production, and panel making, drastically reducing machine downtime and increasing throughput.

Precision and Structural Integrity

Engineered for high rigidity with a robust steel body and aluminum table, the router delivers excellent accuracy. The rack and pinion drive system for the X/Y axes and a ball screw on the Z axis support smooth, repeatable movements, maintaining a repositioning accuracy of 0.02mm even at speeds up to 25,000 mm/min.

Flexible Control and Compatibility

Users can choose between a DSP handheld controller or an NC Studio system for machine operation. The router integrates easily with major design software such as ArtCAM, Type3, and Aspire, ensuring flexible workflow and supporting standard file formats, making it accessible for varied applications.

FAQs of CNC Engraving Router Machine 2 spindle:

Q: How does the double spindle feature improve production efficiency?

A: The twin 3.5 kW spindles can operate simultaneously, either duplicating jobs or handling two separate patterns at once. This capability reduces cycle times and allows higher throughput, particularly in industrial settings where speed and volume matter.Q: What materials can this CNC router process effectively?

A: This machine can engrave and cut wood, MDF, acrylic, PVC, and aluminum. Its high rigidity and strong spindle power ensure clean, precise results across a broad spectrum of rigid and semi-rigid materials.Q: When should I opt for the DSP handheld controller versus NC Studio?

A: The DSP handheld controller is suitable for users seeking straightforward, on-machine operation without a dedicated PC. NC Studio is preferred for more advanced features, including intricate design editing and integration with CAM software in a computer-aided workflow.Q: Where can this CNC engraving router be installed, and what are its environmental requirements?

A: The machine should be set up indoors on a stable surface, within a temperature range of 0-45C and relative humidity of up to 85%. Standard electrical input is 220V or 380V (as customized), making it suitable for most industrial workshops.Q: What is the process for maintaining the water-cooled spindle system?

A: Routine maintenance includes regularly checking the water pump, inspecting coolant levels, and ensuring hoses are free from clogs. This helps maintain optimal spindle temperature, prolonging motor life and ensuring consistent engraving quality.Q: How does the safety protection system safeguard operators?

A: Safety features include emergency stop buttons and limit switches, which help prevent accidental injuries or machine damage by instantly halting operation or restricting movement beyond safe limits.Q: What benefits does high repositioning accuracy provide in practical use?

A: With 0.02 mm repositioning accuracy, the machine can execute detailed patterns and precise cuts, essential for high-value projects like decorative panels, furniture elements, or aluminum signage, where even minor deviations can impact final quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Engraving Machine Category

CNC Pattern Making Machine

Minimum Order Quantity : 1 Unit

Product Type : CNC Pattern Making Machine

Table Size : Customizable / 1500 x 3000 mm (as example)

Material : Other, Wood, Plastic, Foam, Aluminum

Dimension (L*W*H) : 2500 x 2200 x 1800 mm (approx.)

Motor : Other, AC Servo Motor

Industrial CNC Engraving Machine

Minimum Order Quantity : 01 Unit

Product Type : Industrial CNC Engraving Machine

Table Size : 600 mm x 900 mm

Material : Other, Cast Iron and Steel

Dimension (L*W*H) : 1500 mm x 1200 mm x 1400 mm

Motor : Other, Servo Motor

CNC Wood Engraving Router Machine

Product Type : CNC Wood Engraving Router Machine

Table Size : 1300 mm x 2500 mm

Material : Other, Mild Steel, Cast Iron, Aluminium Base

Dimension (L*W*H) : 2050 mm x 3100 mm x 1700 mm

Motor : Other, Stepper Motor / Servo Motor (Optional)

CNC Router Engraving Machine

Product Type : CNC Router Engraving Machine

Table Size : 1300 mm x 2500 mm

Material : Other, Steel and Aluminum Structure

Dimension (L*W*H) : approximately 2000 mm x 3000 mm x 1600 mm

Motor : Other, Stepper Motor

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS