CNC STONE ENGRAVING 2 SPINDLE WITH ROTARY

CNC STONE ENGRAVING 2 SPINDLE WITH ROTARY Specification

- Z axis transmission

- Ball Screw

- Spindle

- 2 x 3.5 kW Water-cooled Spindles

- Marking Depth

- 0-200 mm (Adjustable)

- Marking Speed

- 0-6000 mm/min

- Marking Area

- 1500 x 3000 mm

- X axis Transmission

- Rack and Pinion

- Working Temperature

- 0C - 45C

- Y axis Transmission

- Rack and Pinion

- Design

- Heavy Duty Welded Frame

- Voltage

- 220V/380V (Customizable)

- Machine Type

- CNC Stone Engraving Machine

- Power Supply

- AC 220V/50Hz

- Control System

- DSP A18 Controller

- Accuracy Level

- 0.05 mm

- Weight

- Approx. 1800 kg

- Condition

- New

- Engraving Area

- 1500 x 3000 mm

- Engraving Speed

- 0-6000 mm/min

- CNC

- Yes

- Cooling Mode

- Water Cooling

- Applicable Material

- Granite, Marble, Stone, Tombstone, Ceramic

- Dimensions

- Approx. 2200 x 3500 x 1600 mm

- Drive Type

- Servo Motor Drive

- Motor

- Leadshine/Delta Servo Motor

- Working Area

- 1500 x 3000 mm with 4th Axis Rotary Attachment

- Safety Protection

- Limit Sensors, Emergency Stop Button

- Max Engraving Height

- 200 mm

- Controller Memory

- 128 MB

- Rotary Axis Diameter

- Up to 300 mm

- Rotary Axis Length

- 1500 mm

- Lubrication System

- Automatic

- Spindle Speed

- 0-18000 RPM

- Table Surface

- T-Slot Table with Clamps

- Dust Collection

- Optional

- Transmission Accuracy

- High Precision Gear Transmission

- Software Compatibility

- ArtCAM, Type3, JD Paint, Ucancam

CNC STONE ENGRAVING 2 SPINDLE WITH ROTARY Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- AHMEDABAD

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cheque

- Supply Ability

- Unit

- Delivery Time

- 45 Days

- Packaging Details

- AS PER REQUIREMENT

- Main Domestic Market

- All India

- Certifications

- MSME, MAKE IN INDIA, SMERA

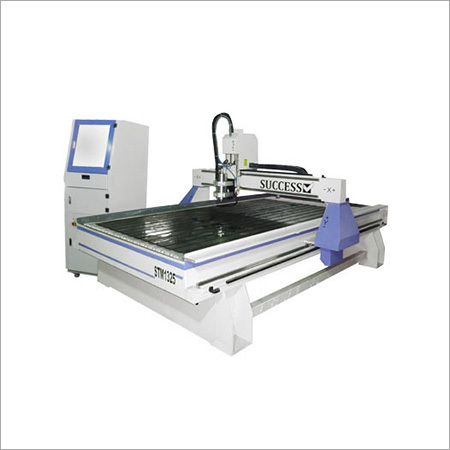

About CNC STONE ENGRAVING 2 SPINDLE WITH ROTARY

CNC STONE ENGRAVING 2 SPINDLE WITH ROTARY is a high speed specialized machine that is commonly used in marble industries to make elegant engraving design with high precision and accuracy. This machine is capable to make engraved designs on various types of materials. The advanced CNC controlled machine comes with high performance drives to ensure controlled and efficient movement of spindles. CNC STONE ENGRAVING 2 SPINDLE WITH ROTARY is capable to make designs on regular as well as irregular surfaces. Get this fully automated machine with an assurance of fast and safe delivery at a reasonable price.

Product details

| Automation Grade | Automatic |

| Model Number | STM2736-2Z |

| Drive Motor | SERVO |

| Power Source | Electric |

| Brand | Success |

| Condition | New |

Exceptional Rotary Engraving Capability

With a rotary axis accommodating up to 300 mm in diameter and 1500 mm in length, this CNC stone engraving machine allows for precision carving on cylindrical objects. This versatility is advantageous for jobs such as column, statue, or cylindrical tombstone design, accommodating a broad range of industrial and creative applications.

Advanced Software and Control System

The machine is compatible with leading design software such as ArtCAM, Type3, JD Paint, and Ucancam, ensuring smooth integration into diverse production environments. The DSP A18 controller paired with 128 MB memory enhances efficiency and provides a user-friendly interface for managing complex engraving projects.

Heavy-Duty Construction and Precision

A robust welded frame and high-precision gear and ball screw transmission systems give the machine superb durability and accuracy. The table features a T-slot surface with secure clamps, keeping your materials steady while you work. Safety features like emergency stops and limit sensors further ensure operational security.

FAQs of CNC STONE ENGRAVING 2 SPINDLE WITH ROTARY:

Q: How does the rotary axis enhance the CNC stone engraving process?

A: The rotary axis allows the machine to engrave cylindrical or curved surfaces up to 300 mm in diameter and 1500 mm in length, expanding its functionality beyond flat workpieces. This is ideal for producing columns, vases, and other round stone products with high precision.Q: What materials can be engraved using this CNC stone engraving machine?

A: The machine is purpose-built for granite, marble, stone, tombstone, and ceramic materials, offering flexibility for a variety of industrial, memorial, and decorative projects.Q: When should I use dual spindles in my engraving operations?

A: Dual spindles are best utilized for simultaneous operations on two separate workpieces or for increasing production efficiency by enabling parallel processing. This helps speed up job throughput, especially in high-volume manufacturing environments.Q: Where can this machine be installed and operated?

A: The CNC Stone Engraving 2 Spindle with Rotary is designed for industrial workshops, manufacturing units, and stone processing facilities. Its robust construction and adjustable working environment requirements (0C to 45C) ensure reliable performance in various workplace settings throughout India and for export markets.Q: What is the process for starting a project on this CNC machine?

A: Begin by designing your project using compatible software (ArtCAM, Type3, JD Paint, or Ucancam). Load the program to the DSP A18 controller, secure your workpiece on the T-slot table or rotary axis, and select desired parameters for spindle speed, marking depth, and speed. Engage safety checks before operation.Q: How does the automatic lubrication system benefit machine performance?

A: Automatic lubrication ensures smoother movement of the transmission components and reduces wear, enhancing performance consistency and extending the machines operational lifespan with less downtime for manual maintenance.Q: What are the primary benefits of using this CNC stone engraving machine?

A: Key advantages include high-speed, precise engravings, versatility for both flat and rotary jobs, sturdy heavy-duty construction, advanced safety features, and seamless software compatibility, all contributing to improved productivity and finished product quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stone Engraving Machine Category

STX 1325 CNC Stone Engraving Machine

Condition : New

Spindle : 5.5KW WaterCooling Spindle

Motor : High Torque Stepper Motors

Drive Type : Stepper Motors

Cooling Mode : WaterCooled, Other

Applicable Material : Stone Marble Granite, Other

Automated Modish Technology Stone Engraving Machine

Condition : New

Spindle : 3.2KW Watercooled spindle

Motor : Highly efficient servo motor

Drive Type : Stepper motor drive

Cooling Mode : Other, Water cooling system

Applicable Material : Stone Marble Granite, Other

STM 1325 CNC Stone Engraving Machine

Condition : New

Spindle : 5.5 kW Water Cooled Spindle

Motor : Stepper Motor

Drive Type : Ball Screw Drive

Cooling Mode : Water Cooling

Applicable Material : Other, Granite, Marble, Stone, Tile, Glass, Jade

CNC Stone Router

Condition : New

Spindle : 3.2 kW Water Cooled Spindle

Motor : Stepper Motor

Drive Type : Stepper Motor Drive

Cooling Mode : Water Cooling

Applicable Material : Other, Stone Marble Granite

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS