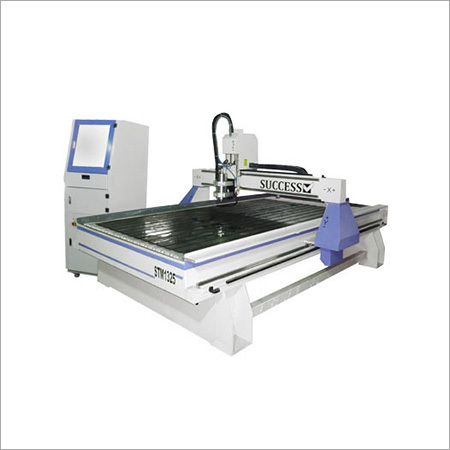

STM 1325 CNC Stone Engraving Machine

STM 1325 CNC Stone Engraving Machine Specification

- Accuracy Level

- 0.05 mm

- Weight

- 1300 kg

- Y axis Transmission

- Rack & Pinion

- Machine Type

- CNC Stone Engraving Machine

- Spindle

- 5.5 kW Water Cooled Spindle

- Control System

- Ncstudio/ DSP controller

- Power Supply

- AC 220V/380V, 50/60Hz

- Marking Area

- 1300 x 2500 mm

- Voltage

- 220V/380V

- Laser Type

- Not Applicable (Spindle-driven)

- Design

- Heavy Duty, Industrial grade

- X axis Transmission

- Rack & Pinion

- Marking Speed

- 8000 mm/min

- Marking Depth

- Up to 150 mm (depending on material)

- Working Temperature

- 0C - 45C

- Z axis transmission

- Hiwin Linear Guideway

- Condition

- New

- Engraving Area

- 1300 x 2500 mm

- Engraving Speed

- 8000 mm/min

- CNC

- Yes

- Cooling Mode

- Water Cooling

- Applicable Material

- Granite, Marble, Stone, Tile, Glass, Jade

- Dimensions

- 3200 x 2100 x 1800 mm

- Drive Type

- Ball Screw Drive

- Motor

- Stepper Motor

- Working Area

- 1300 x 2500 mm

- Tool Holder

- ER25

- Interface

- USB/ Parallel

- Emergency Stop

- Integrated

- Resolution

- 0.01 mm

- Body Material

- Steel welded construction

- Software Compatibility

- ArtCAM, Type3, JD Paint, UG, AutoCAD

- Lubrication

- Automatic lubrication system

- Max Feed Rate

- 12000 mm/min

- Repeatability

- 0.05 mm

- Protective System

- Overload, Over-current

- Table Surface

- T-slot Aluminum Table

- Operation Mode

- Automatic and Manual

- Transmission Type

- Gear & Rack

- Power Consumption

- 6.5 kW

- Max. Tool Diameter

- 12 mm

About STM 1325 CNC Stone Engraving Machine

Ever since our inception, we are the certified manufacturer and exporter of a premium quality range of Stone Engraving Machine. Adopting with advanced DSP system this machine is used for engraving cylinder work piece by simple gantry movements. Under the supervision of our professionals, these machines are properly assembled by utilizing finest grade components in line with global industry standards. This Stone Engraving Machine is properly tested by our quality controllers on various standards and can be availed at pocket friendly price.

Technical Specifications :

| MODEL | STM 1325 |

| Working (X, Y, Z) | 1300 X 2500 x 200 mm |

| Spindle Motor | 5.5 KW (Water Cooled) Optional : 3 KW |

| Max. Running Speed (Without load) | 20m / min |

| Rotating Speed of spindle | 0-18000 rpm |

| Engraving Tool | 3.175, 4, 6, 12.7mm (optional) |

| Dictate Format | HPGL, G-code |

| Repeated Location | 0.025 mm |

| Driving System | Stepper Motor (Optional : Servo Motor) |

| Operating System | PCI Based Controlled (Optional : DSP Hand Held Controller) |

| Power Supply | AC 420V/ 3 PH |

Advanced Precision and Durability

Built with a heavy-duty steel welded frame and high-quality drive components like Hiwin linear guideways and rack & pinion transmission, the STM 1325 ensures long-lasting precision. Resolution up to 0.01 mm and repeatability of 0.05 mm make it suitable for detailed engraving, while industrial-strength construction guarantees consistent performance in high-volume operations.

Versatile Operation and Compatibility

This CNC stone engraving machine integrates automatic and manual operation modes, supporting a variety of working styles. Compatibility with ArtCAM, Type3, JD Paint, UG, and AutoCAD gives users flexibility for diverse design workflows. Its user-friendly Ncstudio/DSP controllers and USB or parallel interfaces streamline connectivity and operation.

Efficient and Safe Working Environment

With features like automatic lubrication, overload and over-current protection, and an integrated emergency stop, the STM 1325 prioritizes operator safety and machine sustainability. A robust 5.5 kW water-cooled spindle enables high-speed production with minimal downtime, while the power-efficient 6.5 kW system keeps operations cost-effective.

FAQs of STM 1325 CNC Stone Engraving Machine:

Q: How is the STM 1325 CNC Stone Engraving Machine typically used in manufacturing?

A: This machine is designed for engraving, cutting, and shaping materials such as granite, marble, stone, tile, glass, and jade. Common applications include creating signage, memorial plaques, decorative wall panels, flooring inlays, and customized sculptures for architectural and artistic purposes.Q: What software programs are compatible with the STM 1325 for design and engraving tasks?

A: The STM 1325 works seamlessly with popular software such as ArtCAM, Type3, JD Paint, UG, and AutoCAD, enabling users to import and execute intricate designs with ease. This compatibility streamlines workflow from design conception to final product.Q: When is it recommended to use automatic versus manual operation modes?

A: Automatic mode is best for repetitive or complex engraving projects requiring precision and speed. Manual mode is useful for setup, prototype work, or when fine adjustments are needed. Switching between modes is straightforward with the integrated Ncstudio or DSP control systems.Q: Where can the STM 1325 be installed and what are the ideal operating conditions?

A: This machine is suited for installation in industrial workshops, stone fabrication facilities, or specialized engraving businesses. It operates optimally in environments with a temperature range of 0C 45C and requires an AC 220V/380V, 50/60 Hz power supply.Q: What is the process for routine maintenance on this engraving machine?

A: Regular maintenance involves checking the ball screw drive and rack & pinion systems for proper lubrication, which is automated, inspecting machine for wear, and ensuring the cooling system functions efficiently. Overload and over-current protection mechanisms add safety and help prevent equipment damage.Q: How does the STM 1325 benefit business operations in terms of efficiency?

A: With a maximum feed rate of 12,000 mm/min, marking speed of 8,000 mm/min, and a spacious working area, the STM 1325 accelerates production cycles. The machines reliability, coupled with low maintenance requirements and automation options, results in consistent output and reduced labor costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stone Engraving Machine Category

CNC STONE ENGRAVING 2 SPINDLE WITH ROTARY

Minimum Order Quantity : 1 Unit

Condition : New

Power Supply : AC 220V/50Hz

Cooling Mode : Water Cooling

CNC : Yes

Voltage : 220V/380V (Customizable)

Automatic Electric Stone Engraving Machine

Condition : New

Power Supply : 220V/50Hz

Cooling Mode : Water Cooling

CNC : Yes

Voltage : 220V

CNC Wood Cutting Machine

Condition : New

Power Supply : AC 220V/50Hz

Cooling Mode : Other, Air Cooling for Spindle

CNC : Yes

Voltage : 220V/380V optional

STM1325-2Z CNC Stone Engraving Machine

Condition : New

Power Supply : AC 220V/50Hz

Cooling Mode : Watercooled spindle, Other

CNC : Yes

Voltage : 220V

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS