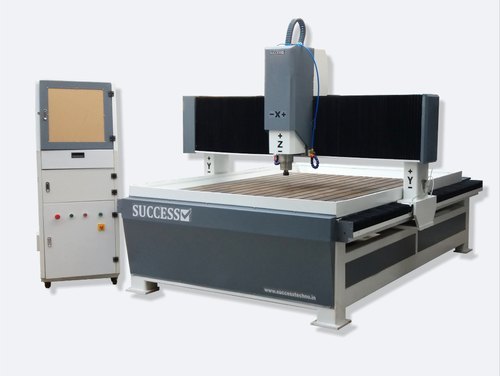

High-Performance CNC Stone Engraving Machine

High-Performance CNC Stone Engraving Machine Specification

- Product Type

- CNC Stone Engraving Machine

- General Use

- Stone Engraving, Cutting, Carving

- Material

- Granite, Marble, Stone

- Type

- CNC Router

- Weight (kg)

- 1800 kg Kilograms (kg)

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Yes

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 4 kW Kilowatt (kW)

- Rigidity

- High

- Voltage

- 380V/50Hz Volt (v)

- Table Size

- 1500 mm x 3000 mm

- Spindle Speed

- 0-24000 rpm RPM

- Axial Choice

- 3 Axis (X, Y, Z)

- Dimension (L*W*H)

- 2200 mm x 3200 mm x 1650 mm Millimeter (mm)

- Color

- White and Blue

- Working Accuracy

- 0.03 mm

- Spindle Motor Power

- 5.5 kW

- Max Engraving Depth

- 180 mm

- Transmission

- Rack and Pinion for X/Y, Ball Screw for Z

- Support Format

- G-code, HPGL, DXF, PLT, etc.

- Cooling System

- Water Cooled Spindle

- Max Traveling Speed

- 25000 mm/min

- Lubrication System

- Automatic

- Dust Collection

- Optional

About High-Performance CNC Stone Engraving Machine

STONE ENGRAVING MACHINE WITH 2 HEAD

Ever since our inception, we are the certified manufacturer and exporter of a premium quality range of STONE ENGRAVING MACHINE WITH 2 HEAD. Adopting with advanced DSP system this machine is used for engraving cylinder work piece by simple gantry movements. Under the supervision of our professionals, these machines are properly assembled by utilizing finest grade components in line with global industry standards. This STONE ENGRAVING MACHINE WITH 2 HEAD is properly tested by our quality controllers on various standards and can be availed at pocket friendly price.

Features:

-

Easy to operate

-

Simpler installation

-

Durable design

Precision and Power for Demanding Stonework

With a 5.5 kW spindle motor and impressive accuracy of 0.03 mm, this CNC router guarantees intricate and clean engravings on stone materials. Its heavy-duty build reduces vibration, enabling consistent results over large workpieces. The water-cooling system enhances spindle longevity, making it efficient for continuous operation.

User-Friendly and Versatile Operation

Driven by an NC Studio or DSP Controller and compatible with multiple industry-leading software like ArtCAM, Type3, and Mastercam, setup and programming are straightforward. The machine supports widely used file formats, ensuring seamless workflow integration for different project needs.

Efficient Automation and Maintenance

Equipped with an automatic lubrication system and optional dust collection, routine upkeep is minimized for operators. The machines high power efficiency and computerized controls streamline production, reducing labor and operational costs while maximizing output.

FAQs of CNC Stone Engraving Machine:

Q: How does the CNC Stone Engraving Machine ensure high precision during operation?

A: This machine is engineered for high accuracy, featuring a finely tuned rack and pinion transmission for X/Y axes, a ball screw for the Z axis, and a water-cooled spindle. The heavy-duty construction further minimizes vibration, maintaining a working accuracy of 0.03 mm for detailed stonework.Q: What types of stones and applications is this machine suitable for?

A: Designed for granite, marble, and other stone materials, the machine is ideal for engraving, cutting, and 3D carving. It efficiently handles one stone panel per cycle, making it perfect for manufacturing, construction, and artistic stone processing.Q: When is dust collection recommended during operation?

A: Dust collection is optional but highly recommended for extensive cutting or engraving sessions where fine stone dust may accumulate. Installing a dust collection system helps maintain a cleaner working environment and protects the machines internal components from debris.Q: Where can I integrate this CNC router into my workflow?

A: This CNC router fits seamlessly into stone-processing workshops, factories, or any facility involved in stone engraving, cutting, or finishing. Its compatibility with common design software and file formats simplifies integration with existing production lines.Q: What is the typical process for using the CNC Stone Engraving Machine?

A: Begin by designing your pattern using compatible software such as ArtCAM or Mastercam. Import your design file to the machines controller, secure the stone panel on the 1500 x 3000 mm table, and select the appropriate spindle speed. The automatic lubrication and water cooling systems handle maintenance during operation, ensuring smooth, uninterrupted engraving or milling.Q: What are the main benefits of this CNC Stone Engraving Machine for my business?

A: The machines automated, computerized controls and high rigidity structure deliver consistent quality, reduce manual intervention, and boost production efficiency. Its compatibility with multiple software platforms and file formats provides flexibility for varied projects, while automated features like lubrication lower ongoing maintenance needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Engraving Machine Category

Industrial CNC Engraving Machine

Minimum Order Quantity : 01 Unit

Product Type : Industrial CNC Engraving Machine

Power Source : Electric

Weight (kg) : 950 kg

Type : Other, CNC Engraving Machine

CNC Router Engraving Machine

Product Type : CNC Router Engraving Machine

Power Source : Electric

Weight (kg) : Approx. 1200 kg

Type : CNC Router

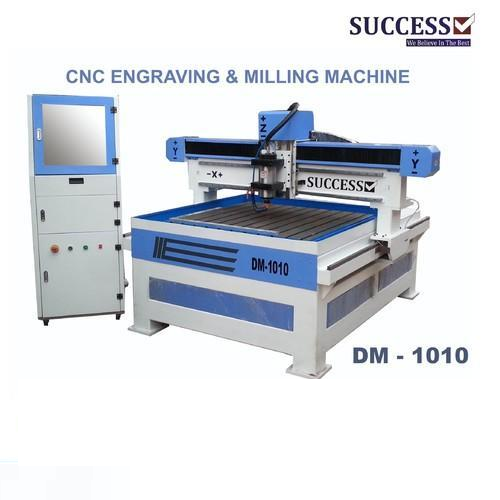

CNC Engraving & Milling Machine

Product Type : CNC Engraving & Milling Machine

Power Source : Electric

Weight (kg) : 1800 kg

Type : Other, CNC Milling Machine

CNC Engraving & Router Machine with Rotary Attachment

Product Type : CNC Engraving & Router Machine with Rotary Attachment

Power Source : Electric

Weight (kg) : Approx. 1200 1600 kg

Type : Other, CNC Router & Engraving Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS